AVX | High Reliability, Defense & Space Applications

AVX has over 30 years experience in producing industry-leading, high-reliability passive components, offering an expanding range of products for defense, aerospace, space and other high reliability industries.

About AVX

AVX Corporation is a leading supplier of advanced components and interconnect solutions, offering the world’s broadest selection of passive components and connectors

AVX currently has 11 factories in Europe and USA qualified to AS9100, IECQ-CECC, TS16949-2009 and ISO 9001-2008 standards. The company also has a number of products qualified to COTS+, ESCC, SRC, MIL and DSCC drawings, as well as optional custom screening and test service capabilities. As a technology leader, AVX will continue to add to its product portfolio on a regular basis.

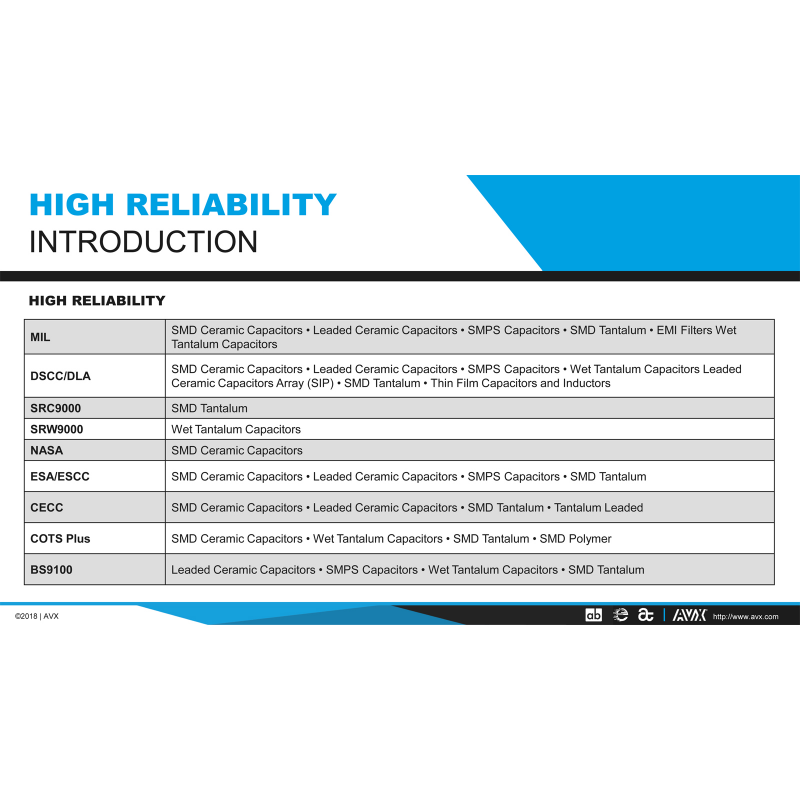

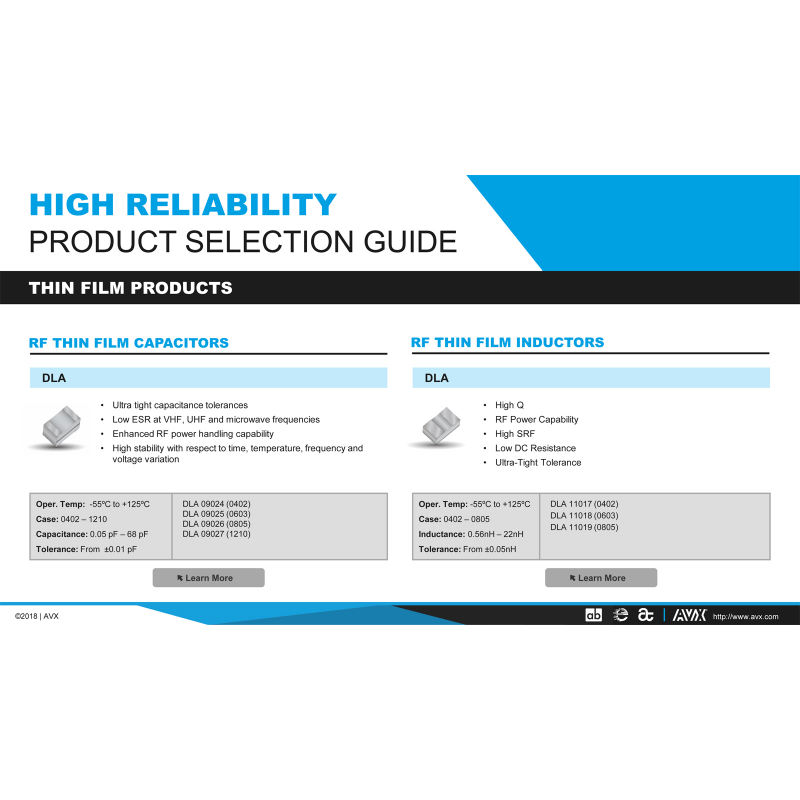

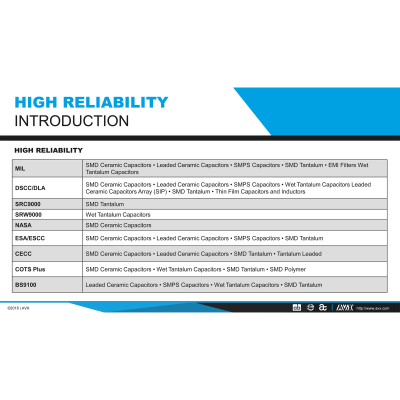

High Reliability Approvals

|

Approval Type |

Components Approved |

| MIL |

|

| DSCC/DLA |

|

| SRC9000 |

|

| SRW9000 |

|

| NASA |

|

| ESA/ESCC |

|

| CECC |

|

|

COTS Plus |

|

|

BS9100 |

|

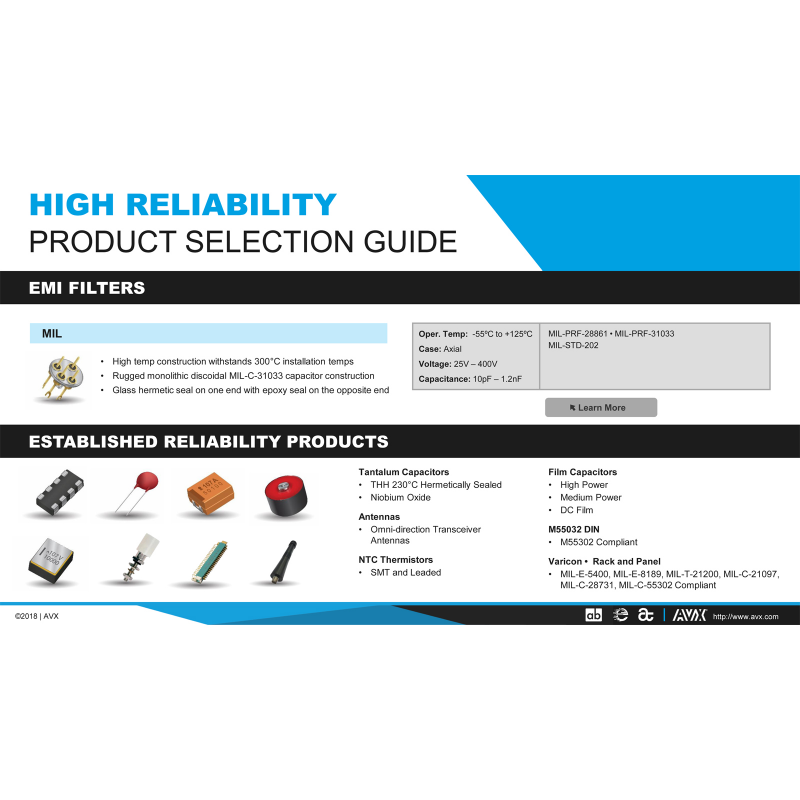

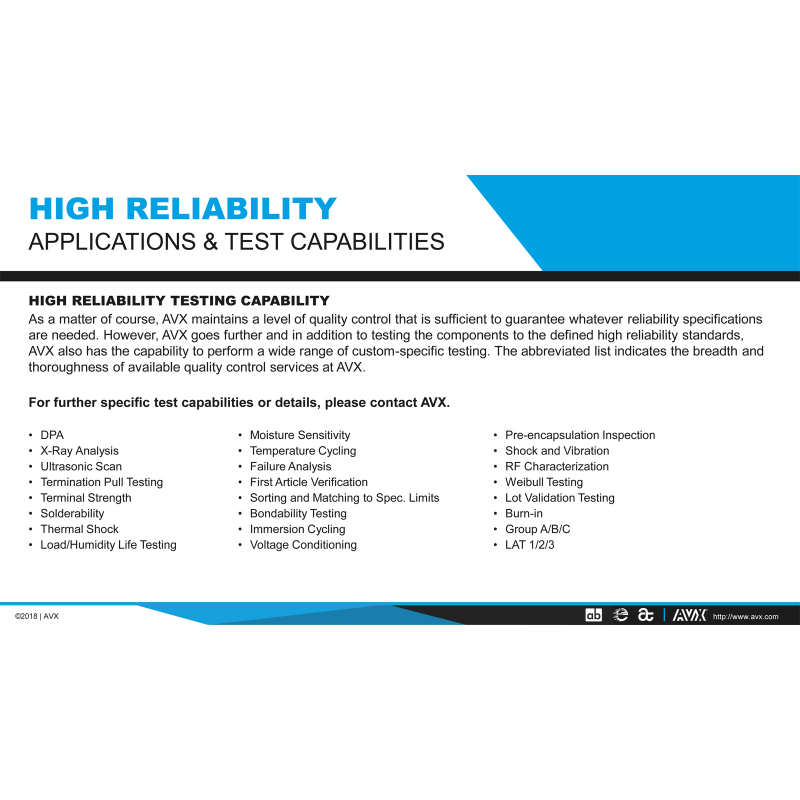

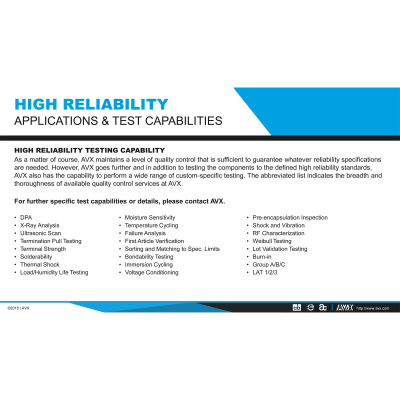

High Reliability Testing Capability

As a matter of course, AVX maintains a level of quality control that is sufficient to guarantee whatever reliability specifications are needed.

However, AVX goes further and in addition to testing the components to the defined high reliability standards, AVX also has the capability to perform a wide range of custom-specific testing. The abbreviated list indicates the breadth and thoroughness of available quality control services at AVX.

|

|

|

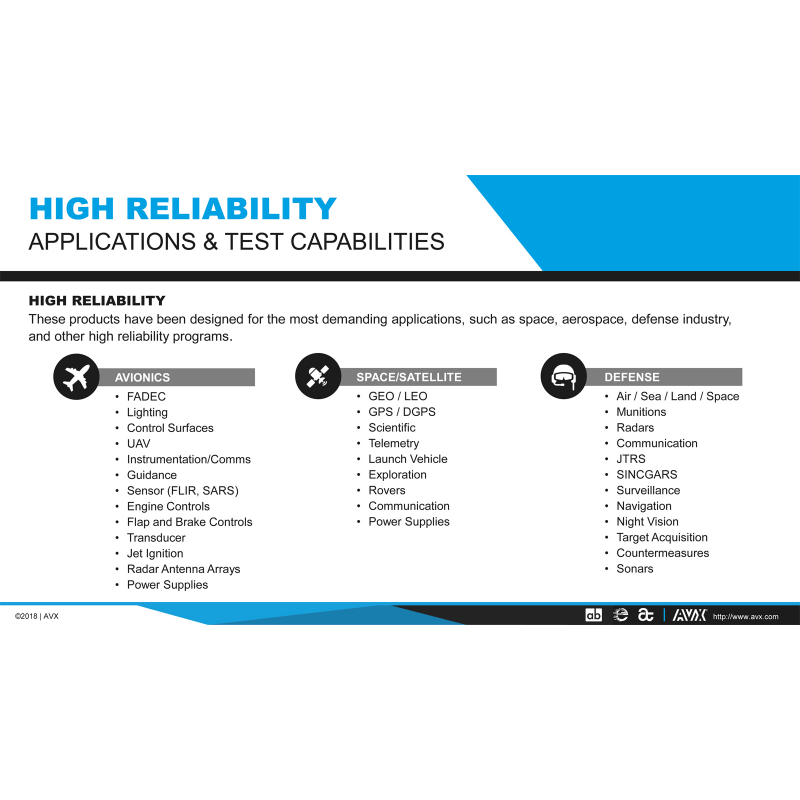

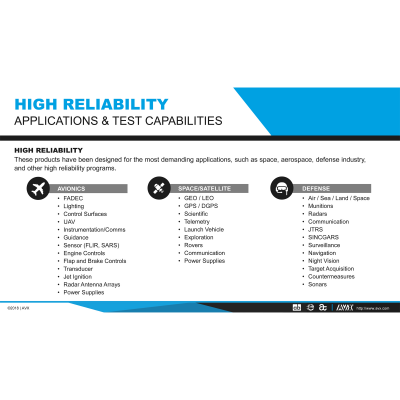

Applications

| Avionics |

Space / Satellite |

Defense |

|

|

|

A Little about DMTL and AVX

DMTL is a fully franchised, authorised distributor for AVX and has enjoyed an extremely close and successful relationship with AVX for over 30 years.

Commencing as a direct customer in 1988, DMTL was then appointed as AVX UK Design Distributor in 1996.

Of note is the fact that for the last 5 years, DMTL has continued, by some margin, to be AVX’s Top Design Distributor for the UK, by value, each year.. This being a clear indicator of the strength of AVX’s technical support, in their partnership with DMTL