MLCC Replacement Options | Tantalum Chip Substitution

The MLCC capacitor market is currently going through a tough supply period.

MLCC manufacturers are not able to service all of their high volume, consumer and Automotive segments. This is resulting in considerable MLCC shortages that may take several years to be resolved.

This may limit end electronic users production and is causing serious market concerns with risks of line stop situations. Over the decades MLCCs Class II capacitors were replacing tantalum capacitors, mostly due to the price and availability reasons. It may be good to refresh some of the basic replacement guidelines from the opposite direction – replacing MLCC class II by tantalum and NbO capacitors – based on the current situation in the market , to be ready and flexible.

MLCC current leadtimes on certain types may reach as long as 40 to 60 weeks!, and it remains tight in May, tantalum capacitors are getting tighter as well, nevertheless at the time of writing of this article they can still offer half the leadtime on a number of possible replacement parts. This also includes NbO capacitors, (sister parts to tantalum capacitors), with many similar features and despite this, they occupy a relatively small percentage of the market, they should be included in the list of considered alternatives to provide wider flexibility and options.

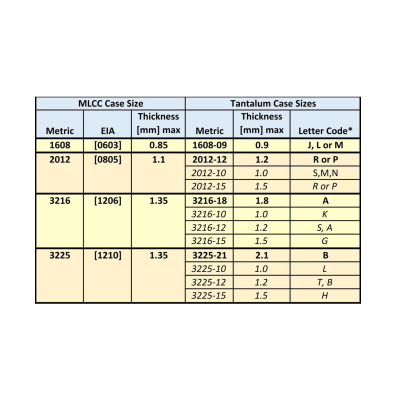

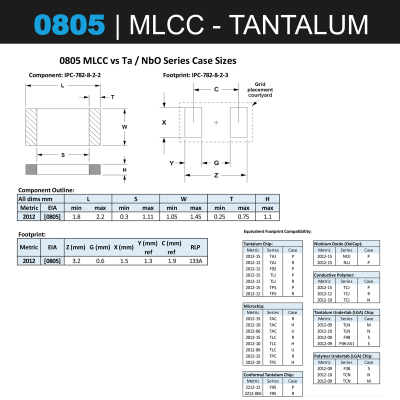

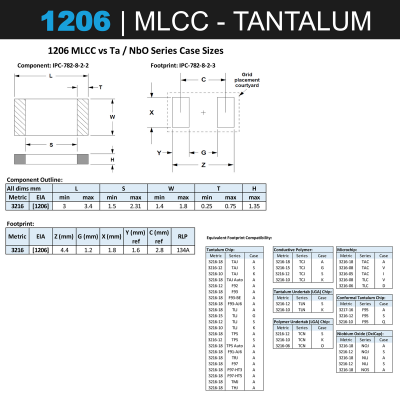

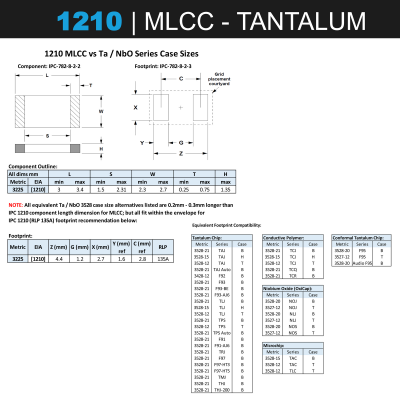

Case Sizes and Pad Dimensions

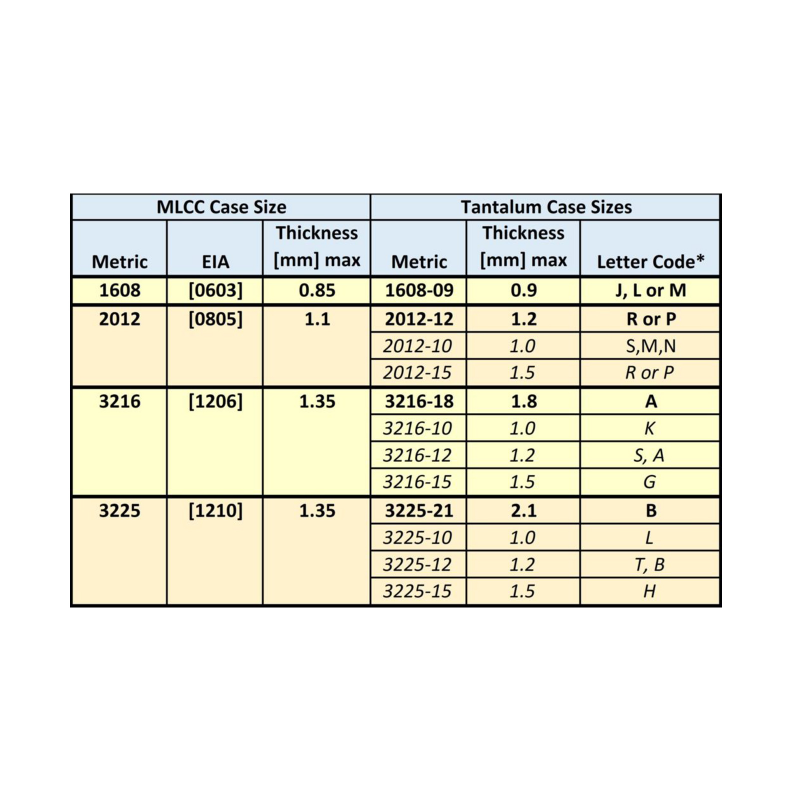

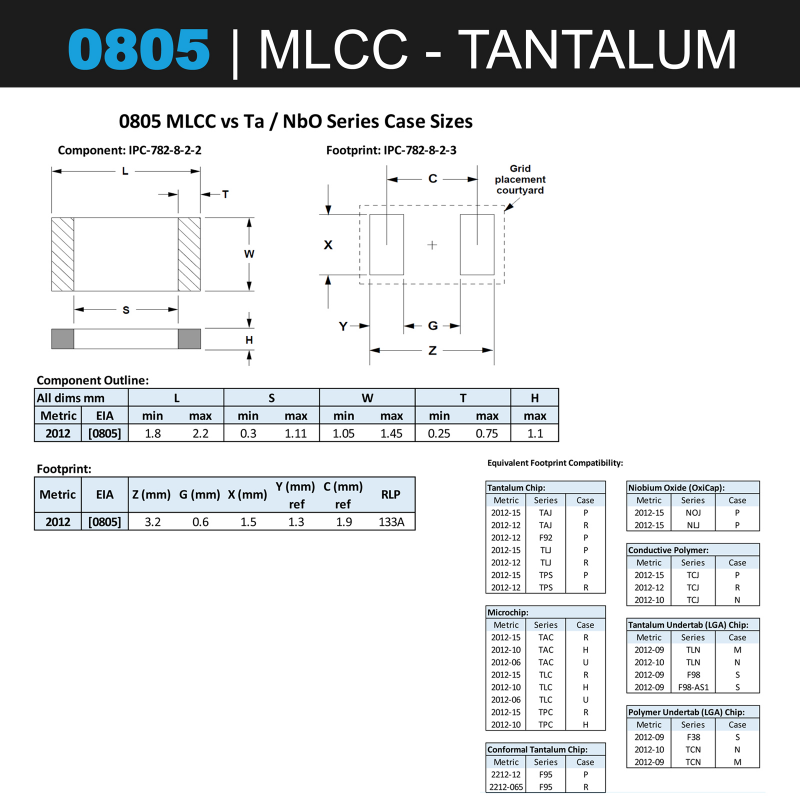

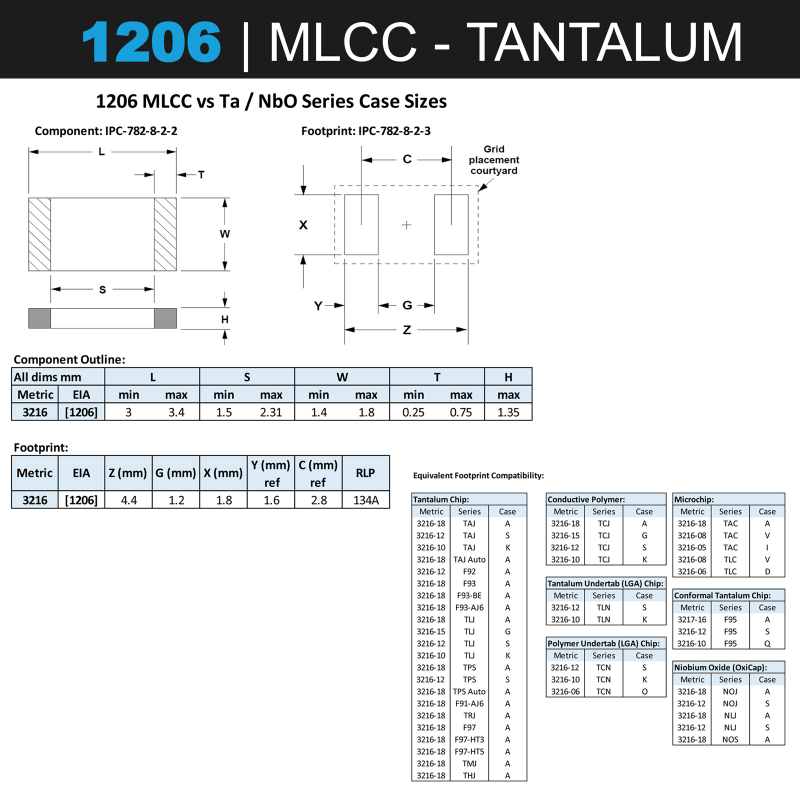

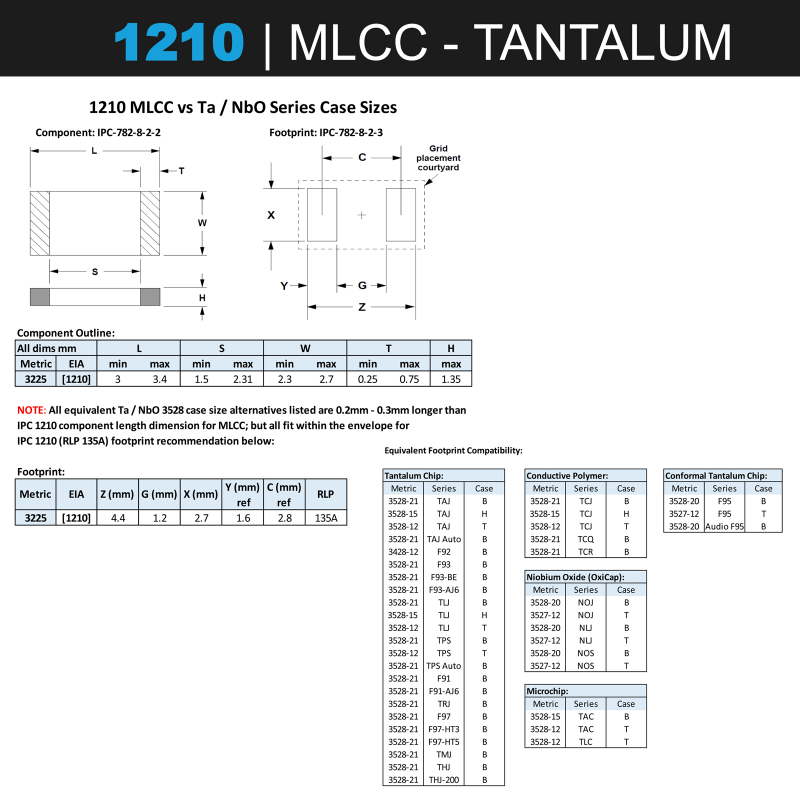

MLCC and tantalum/NbO footprints and pad designs are compatible for at least the basic case sizes 0603, 0805, 1206 and 1210 thus, board PCB pad re-design is not normally necessary . Nevertheless, some attention has to be paid to the component thickness (max height) for head to head replacement. The table in the gallery shows some cross comparison of case sizes between MLCC and tantalum/NbO capacitors. Please note that the tantalum letter code may be manufacturer and series specific, especially in its low profile version.

From the technology stand point, MLCCs are good in making parts physically smaller, tantalums answer better, the needs for thin and flat designs. For example, if the task is to get maximum capacitance within 1.0mm max height, tantalum capacitors can make a larger thinner part with high capacitance in a mechanically strong body, unlike the MLCCs that could lead to a fragile design with risk of cracking. In reality, tantalum capacitors are available in more thickness and low profile case options as seen in Table 1. On the other hand, MLCC technology can go to much smaller dimensions and make smaller capacitors available. (not listed in the Table 1. as not relevant for this comparison).

Volumetric efficiency wise, X7R/X5R MLCCs offer a similar volumetric efficiency today as available with tantalum capacitors or one step higher values at smaller case sizes. Nevertheless MLCC “effective capacitance” in the real operation conditions should be considered as the capacitance value decreases with DC and AC applied voltage compared to tantalum/NbO with stable rated capacitance value.

Cost Matters

In a “stable” market environment, technology based cost for 1206 case MLCC class II and Tantalum capacitors can be very close (depending on capacitance and voltage value). The 1206 case size is a cost down sweet-spot case size for a standard tantalum capacitors and it can be in price competitively positioned as MLCC class II.

MLCC capacitors are manufactured in process sheets that are cut into individual capacitors, its cost down mechasnism (with certain limits and specific product exceptions) is downsizing. Thus, smaller case sizes 0805 and 0603 may be cheaper than 1206, even with a more expensive high tech material used. (as there are more smaller units per one process sheet produced). This is not the case for tantalum/NbO capacitors, where a standard “in-row units” manufacturing technology processing of smaller case sizes below 1206 size is more expensive.

In consequence, 0805 and 0603 tantalum capacitors may be more expensive compared to the MLCC components. However, to be fair to tantalums, it is not that easy and simple a rule, as tantalums are more stable without loss of capacitance with applied voltage, thus in some cases it may end up that the stable performance tantalum cap is a cheaper solution than a MLCC solution that loses capacitance with voltage and time … let’s discuss this more in next chapters……..

0402 and 0201 tantalum case sizes are also available on the market, but are considered as a niche applications with parameters, cost and mass volume capability too far from the MLCC high volume parts to be considered in this article. On the large case size scale, MLCC parts bigger than 1210 are also available, nevertheless the volume is much smaller.

The above discussed cost structure is however only reflective of capacitor pricing in “stable” market conditions. Today, when we are in a short supply situation, the main price driver is becoming “availability”. As a consequence, in example, MLCC prices are expected to rise 40-50% in 2Q18 according to Taiwan based Digitimes.

Key Advantages Overview

- MLCC Class II Advantages

- Low ESR

- High ripple load

- Non-polarized

- Low DCL

- Tantalum/NbO Advantages

- No piezo noise

- stable capacitance with voltage BIAS and temperature

- high mechanical strength, robustness and vibration resistance

- Common Strong Points

- Lead-free standard design and reflow compatibility

- ROHS friendly standard design

- Wide temperature range (-55/+125C ready as a standard)

- Relatively very good basic reliability

- High capacitance in small dimensions

Conclusion - Suitable Replacement Applications

Based on the above discussion and performance comparison one can assume the suitable applications for tantalum to MLCC replacement:

A. LOW RISK:

– all applications, where very low ESR and high ripple current load are not a prime requirement, such as circuit functions – coupling/decoupling including audio circuits, selected filtering, timing etc.

Checklist:

- a) low ESR requirements and high ripple current load Yes/No/Level

- b) DCL leakage level in case of battery operated circuit

Tantalum or NbO capacitors in these applications can represent an even more stable, reliable solution, possibly superior compared with the original MLCC capacitor.

B. MORE DETAILED EVALUATION NEEDED:

– smoothing applications typically at DC/DC converters with high power load requirements.

Checklist:

- a) smoothing frequency required at low frequencies ESR of MLCC capacitors may be even higher than tantalum. Use of tantalum capacitors is thus possible with potentially improved performance.

- b) beware of the required low ESR and ripple load specification values as the critical characteristics as the low ESR may be the main limiting factor for the circuit operation.

- c) return to b) and check the low ESR / ripple load requirements in the entire end device operating temperature range

- d) consider appropriate derating rules for tantalum, NbO and polymer capacitors.

MLCC Replacement Guide

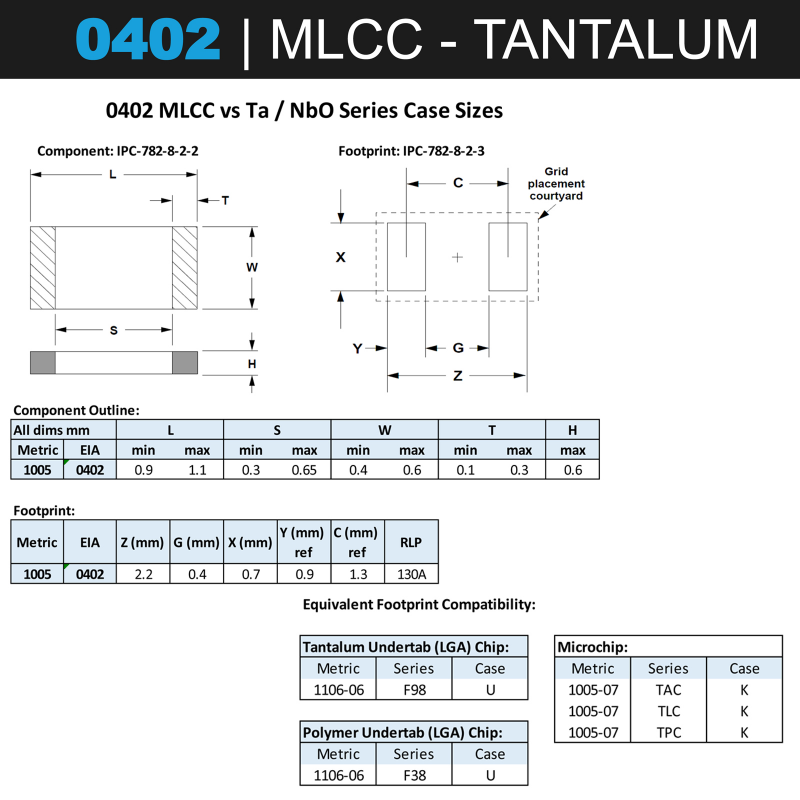

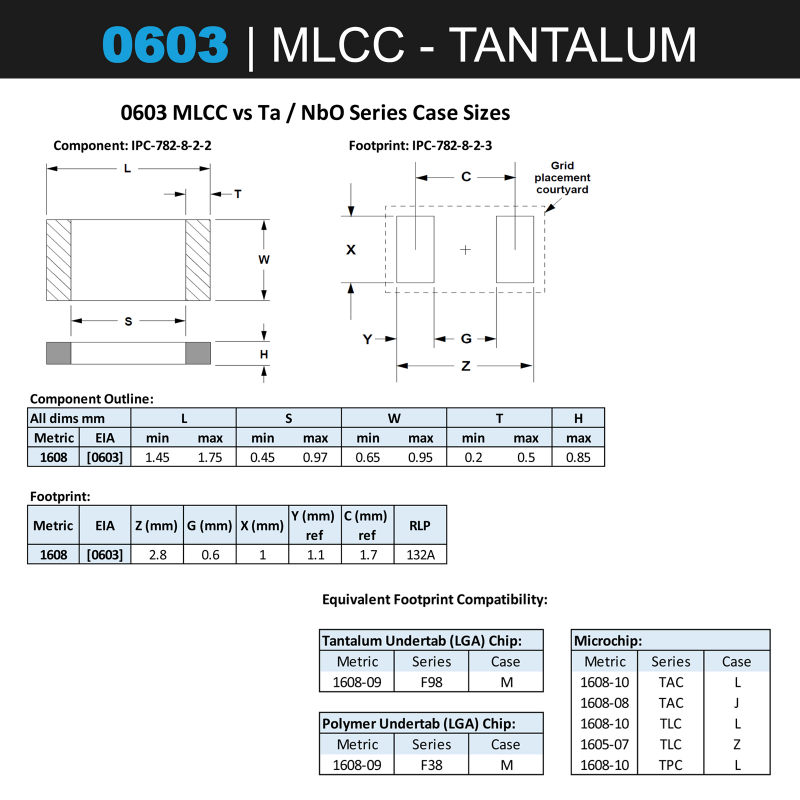

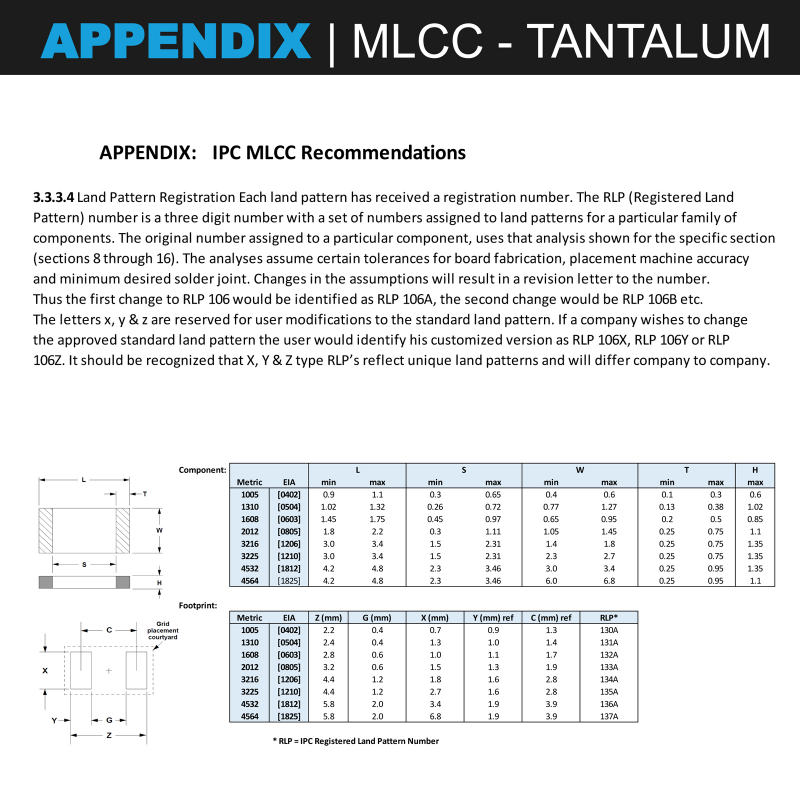

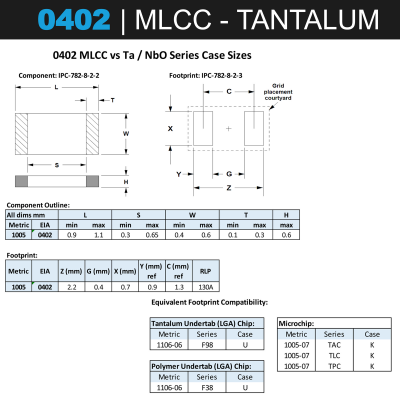

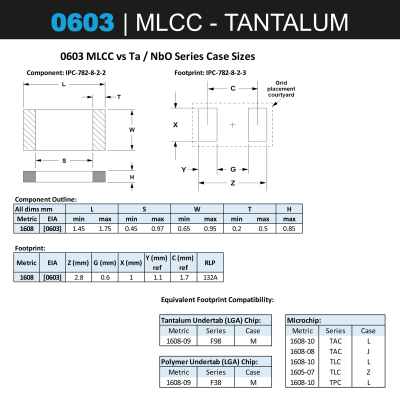

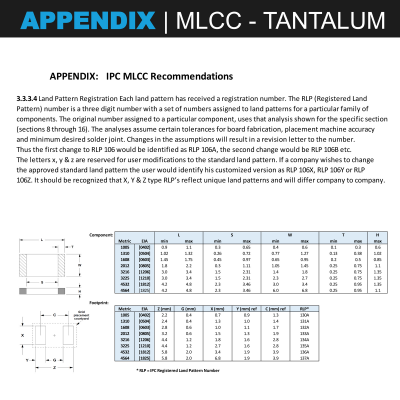

Many years ago, IPC set a standard of recommended footprints for the most classes of surface mount electronic components, including resistors, capacitors and inductors.

Although many companies develop their own internal footprint guidelines, IPC standards for MLCC and tantalum chip are the starting point. At the time they were developed, there was only one common footprint between MLCC & Ta chip - the 1206 size, which is common to both series.

Since that time tantalum chip has added smaller case sizes, designed for compatibility with IPC MLCC footprints. This guide shows, by case size, which tantalum chip series and case sizes fit a common IPC footprint.

As tantalum capacitance / voltage ratings overlap with most Class II ratings (X7R, X5R, X7S etc.), when looking for a substitute first use this guide to establish a footprint compatible tantalum chip series then contact DMTL to establish compatible electrical ratings.

Information source EPCI / AVX Corporation

|

MLCC Case-V-Cap |

MLCC Case |

MLCC V |

MLCC Cap uF |

MnO2 |

MnO2 |

MnO2 |

Polymer |

OxiCap |

| 1210 6 476 | 1210 | 6 | 47 | TAJB476M006RNJ | TAJB476M010RNJ | F930J476MBA | TCJB476M006R0070 | NOJB476M006R |

| 1210 6 475 | 1210 | 6 | 4.7 | TAJB475M016RNJ | F931D475MBA | |||

| 1210 6 226 | 1210 | 6 | 22 | TAJB226M010RNJ | F931A226MBA | TCJB226M010R0300 | NOJB226M006R | |

| 1210 6 107 | 1210 | 6 | 100 | TAJB107M006RNJ | TAJB107M010RNJ | F930J107MBA | TCJB107M006R0070 | NOJB107M006R |

| 1210 6 106 | 1210 | 6 | 10 | TAJB106M016RNJ | F931C106MBA | NOJB106M010R | ||

| 1210 6 105 | 1210 | 6 | 1 | TAJB105M035RNJ | ||||

| 1210 4 476 | 1210 | 4 | 47 | TAJB476M010RNJ | F920G476MBA | TCJB476M006R0070 | NOJB476M004R | |

| 1210 4 475 | 1210 | 4 | 4.7 | TAJB475M016RNJ | F931D475MBA | |||

| 1210 4 226 | 1210 | 4 | 22 | TAJB226M010RNJ | F931A226MBA | TCJB226M010R0300 | NOJB226M004R | |

| 1210 4 107 | 1210 | 4 | 100 | TAJB107M004RNJ | TAJB107M010RNJ | F930G107MBA | TCJB107M004R0070 | NOJB107M004R |

| 1206 6 476 | 1206 | 6 | 47 | TAJA476M006RNJ | F930J476MAA | TCJA476M006R0100 | ||

| 1206 6 475 | 1206 | 6 | 4.7 | TAJR475M010RNJ | F931A475MAA | NOJA475M006R | ||

| 1206 6 226 | 1206 | 6 | 22 | TAJA226M006RNJ | TAJA226M010RNJ | F930J226MAA | TCJA226M006R0300 | NOJA226M006R |

| 1206 6 225 | 1206 | 6 | 2.2 | TAJA225M016RNJ | F931C225MAA | |||

| 1206 6 107 | 1206 | 6 | 100 | F930J107MAA | TCJA107M006R0100 | |||

| 1206 6 106 | 1206 | 6 | 10 | TAJA106M006RNJ | F930J106MAA | TCJA106M006R0300 | NOJA106M006R | |

| 1206 4 476 | 1206 | 4 | 47 | TAJA476M004RNJ | TAJA476M006RNJ | F930G476MAA | TCJA476M004R0200 | NOJA476M006R |

| 1206 4 226 | 1206 | 4 | 22 | TAJA226M004RNJ | TAJA226M006RNJ | F930G226MAA | TCJ226M004R0300 | NOJA226M004R |

| 1206 4 107 | 1206 | 4 | 100 | TAJA107M004RNJ | TAJA107M006RNJ | F930G107MAA | TCJA106M004R0200 | |

| 1206 4 106 | 1206 | 4 | 10 | TAJA106M006RNJ | F930J106MAA | TCJA106M006R0300 | NOJA106M006R | |

| 0805 6 475 | 0805 | 6 | 4.7 | TAJR475M006RNJ | TAJR475M010RNJ | F920J475MPA | NOJP475M006R | |

| 0805 6 226 | 0805 | 6 | 22 | TAJP226M006RNJ | F981A226MSA | F380J226MSA | ||

| 0805 6 225 | 0805 | 6 | 2.2 | TAJR225M006RNJ | TAJR225M010RNJ | F920J225MPA | ||

| 0805 6 106 | 0805 | 6 | 10 | TAJR106M006RNJ | TAJR106M010RNJ | F920J106MPA | NOJP106R006R | |

| 0805 4 475 | 0805 | 4 | 4.7 | TAJR475M004RNJ | TAJR475M006RNJ | F920G475MPA | NOJP475M006R | |

| 0805 4 226 | 0805 | 4 | 22 | TAJR226M004RNJ | TAJR226M006RNJ | F920G226MPA | F380J226MSA | |

| 0805 4 225 | 0805 | 4 | 2.2 | TAJR225M004RNJ | TAJR225M006RNJ | F920J225MPA | NOJP225M010R | |

| 0805 4 106 | 0805 | 4 | 10 | TAJR106M004RNJ | TAJR106M006RNJ | F920G106MPA | NOJP106M004R | |

| 0603 6 476 | 0603 | 6 | 47 | TLCL476M006R | F980J476MMA | F380J476MMAAXE | ||

| 0603 6 475 | 0603 | 6 | 4.7 | TLCL475M006R | TLCL475M010R | F980J475MMA | F381A475MMA | |

| 0603 6 226 | 0603 | 6 | 22 | TLCL226M006R | F980J226MMA | F380J226MMA | ||

| 0603 6 225 | 0603 | 6 | 2.2 | TACL225M006R | TACL225M010R | F981A225MMA | F381A225MMA | |

| 0603 6 106 | 0603 | 6 | 10 | TACL106M006R | TACL106M010R | F980J106MMA | F380J106MMA | |

| 0603 6 105 | 0603 | 6 | 1 | TACL105M006R | TACL105M010R | F981C105MMA | ||

| 0603 4 476 | 0603 | 4 | 47 | TLCL476M004R | TLCL476M006R | F980G476MMA | F380J476MMAAXE | |

| 0603 4 475 | 0603 | 4 | 4.7 | TACL475M004R | TACL475M006R | F980J475MMA | F381A475MMA | |

| 0603 4 226 | 0603 | 4 | 22 | TACL226M004R | TACL226M006R | F980G226MMA | F380J226MMA | |

| 0603 4 225 | 0603 | 4 | 2.2 | TACL225M004R | TACL225M006R | F981A225MMA | F381A225MMA | |

| 0603 4 106 | 0603 | 4 | 10 | TACJ106M004R | TLCJ106M006R | F980J106MMA | F380J106MMA | |

| 0402 6 475 | 0402 | 6 | 4.7 | TLCK4756M006R | F980J475MUA | F380J475MUA | ||

| 0402 6 474 | 0402 | 6 | 0.47 | TACK474M010RTA | F981C474MUA | |||

| 0402 6 225 | 0402 | 6 | 2.2 | TACK225M006RTA | TLCK225M010RTA | F981A225MUA | ||

| 0402 6 106 | 0402 | 6 | 10 | TLCK106M006 | F980J106MUALZT | |||

| 0402 6 105 | 0402 | 6 | 1 | TACK105M006RTA | F380J105MUA | |||

| 0402 6 104 | 0402 | 6 | 0.1 | TACK104M016RTA | ||||

| 0402 4 475 | 0402 | 4 | 4.7 | TLCK475M004RTA | TLCK475M006RTA | F980G475MUA | F380J475MUA | |

| 0402 4 474 | 0402 | 4 | 0.47 | TACK474M010RTA | F981C474MUA | |||

| 0402 4 225 | 0402 | 4 | 2.2 | TACK225M006RTA | F981A225MUA | |||

| 0402 4 105 | 0402 | 4 | 1 | TACK105M006RTA | F380J105MUA |