Passive electronic component obsolescence support

Obsolescence affects the electronics industry in the same way it does our daily lives.

A particular electronic component within a range or an entire series type may become obsolete due to a number of factors. These may include;

- the item no longer being commercially viable to produce

- changes in material legislation

- rationalisation of competing lines

- aging or defunct manufacturing equipment

- a desire for the electronic component manufacturer to move to a more technologically advanced offering, to ensure they remain a leader in their field.

Obsolescence tends not to be recognised as a problem, until it’s a big problem!

How to handle component obsolescence

Companies look to tackle the effects of obsolescence in a number of ways depending on the size of the organisation & the consequences of obsolescence will present.

They may employ engineers and managers to look at only obsolescent items , seek out the services of a third-party contractor, purchase specialist software, or participate in seminars, etc.

Different customers have very different requirements when it comes to obsolescence. The nature of the product and end application normally dictates the chosen approach. For example, a large established defence contractor who has guaranteed service in field of 15+ years of a radar system will be very different to an SME who has in house designed a low-tech consumer grade product.

DMTL’s obsolescence support.

Being a specialist distributor, DMTL is always looking to help customers with whatever approach and resource they have available or need. Below we explore some actual examples:

Sole sourced

Passive electronic components being sole sourced provides a number of headaches when obsolescence bites. Worse-case scenario is that the end product has to be obsoleted itself or completely redesigned, with potentially eye-watering approval costs incurred.

DMTL can assist with suggesting fit, form and functional equivalents, at any stage of the program. Ideally this exercise will be completed at the very beginning of the design\ redesign, as advantages are apparent from the outset as customers have a back-up approved should a particular manufacturer obsolete the device.

Technical Library (Shush!)

One issue when obsolescence of an electronic component emerges is that the product may have been used across multiple designs, spanning decades. It is then not fully understood why the product was selected in the first place and access to the datasheet is sometimes not available.

DMTL continues, as we have done so for over 30 years, to maintain a technical library for the manufacturers we represent, and others. This allows us, in this particular situation, to wind back time, to assess the key characteristics of the component itself and hopefully offer a suitable modern day equivalent.

Notification

If a manufacturer changes or discontinues a product then a franchised specialist distributor will have been provided formal notification in the form of a PCN, EOL or LTB. This allows customers to take appropriate action if needed, to mitigate against any potential impact of the change.

At DMTL we aim to go above and beyond with our support of passive electronic components and if a customer has sent an RFQ for an item, but did not proceed with order placement, we will not hold that small matter against them and we will notify them too!

Samples

One key element in solving an electronic component obsolescence issue is obtaining a suitable replacement(s) – DMTL’s manufacturers are some of the most proactive suppliers offering free of charge samples with a quick turnaround.

Influence

DMTL have, in a number of instances, persuaded the component manufacturer who is making the electronic component obsolete, to continue with either, manufacturing the product or, extending the LTB so that customers can maintain the production of their end product.

Part number variation

Some manufacturers, unfortunately, do change part number configurations. Reasons can include; a new internal system, RoHS/material classification, acquiring or being acquired by another manufacturer – the product itself is sometimes not actually obsolete, only the part number!

DMTL will fully explore the actual status of the component and advise accordingly.

Technical support

Sometimes customers are left with no option but to look at a different technology.

In this instance, engineers will need to work with technically competent partners to understand why the product type was selected in the first place and what elements are vitally important to the application ‘decoupling’ from the application any elements that were just a by-product of the technology (or product) itself.

Related Articles

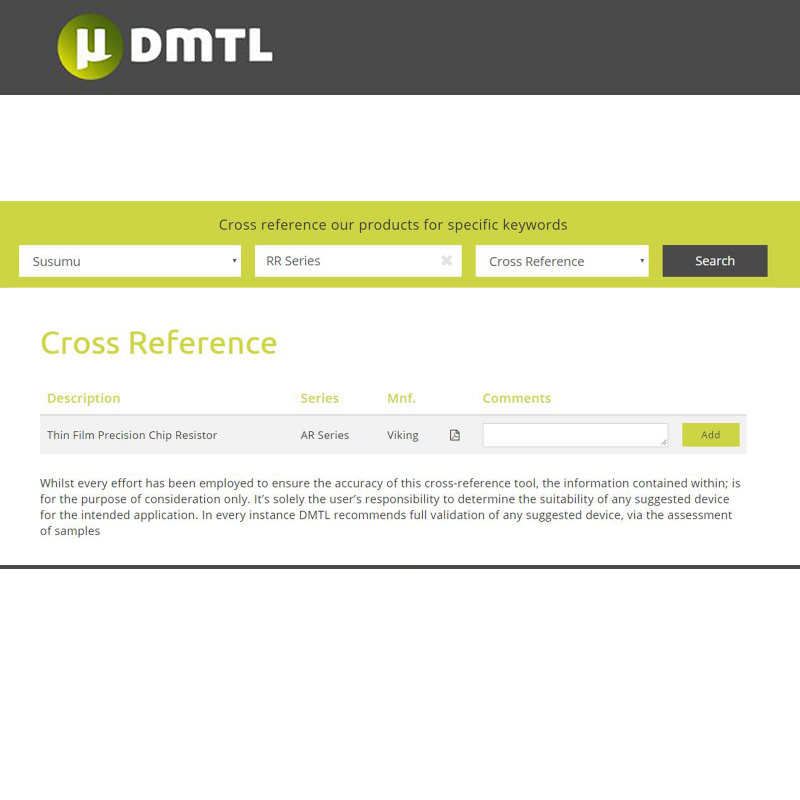

Resistor Alternatives | DMTL's New Cross-Reference Tool

DMTL have developed an online resistor cross-reference tool for engineers and buyers to find alternative parts.

Read more >

DMTL Approved and Fully Registered on the JOSCAR Supplier Accreditation Register

Having been sponsored by one of the prime founding members, DMTL have been approved to join the Joint Supply Chain Accreditation Register (JOSCAR)

Read more >

DMTL | The UK's Leading Design-In Distributor... where designs fly!

If you want to get on board with DMTL, request your Free promotional plane today!

Read more >

A History of DMTL - Founded in 1987...

Throughout the years, DMTL have advertised in many publications and here is a brief history of some of the adverts designed and published by DMTL!

Read more >

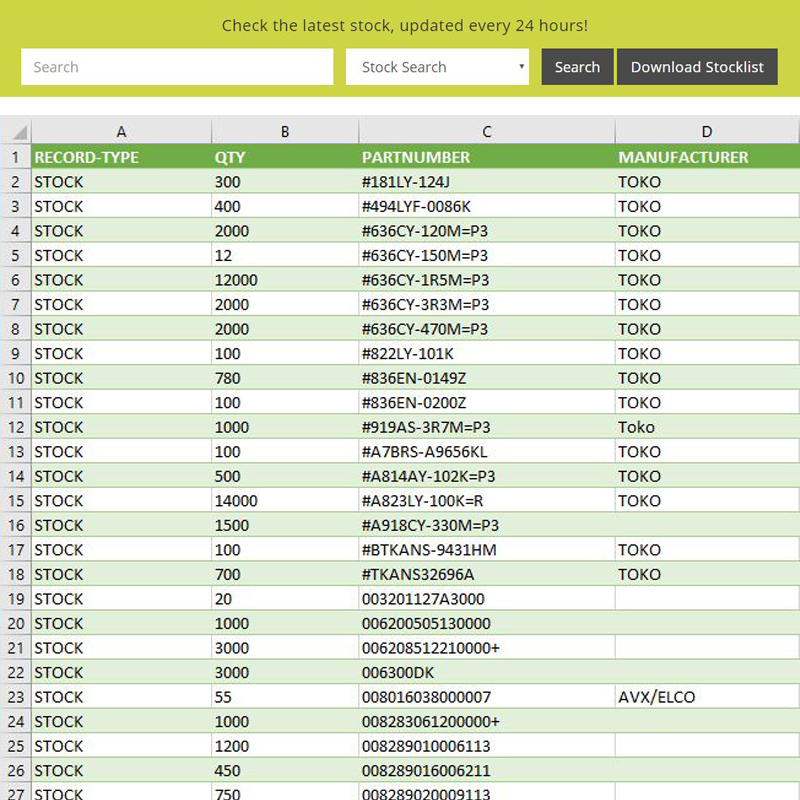

Download our Stocklist - Updated Every 24 Hours!

Using the handy 'Download Stocklist' button on the DMTL homepage, users can download a .csv file with an up-to-date stocklist which is updated every 24 hours!

Read more >

DMTL Now Certified to AS9120

DMTL have successfully transitioned from ISO 9001:2015 to AS9120 RevB (EN 9120:2018) following requests from their growing Hi-Rel customer base.

Read more >

DMTL | The Special Distributor

DMTL operate successfully with companies of all sizes, we provide the support for products which need to be identified, handled and supported very differently from commodity products

Read more >